Monitor - ISSN 1472-0221

The Newsletter for PC-Based Data Acquisition and Control

Issue 195, October 2014

Welcome to Monitor: thanks for subscribing. By popular request the Excel Corner is back (thanks those who wrote). If you have any questions on using Excel in engineering or scientific applications, please e-mail monitor@windmillsoft.com or fill in the form at https://www.windmill.co.uk/excel/excel-tips.html. We'll do our best to answer your question.

Should you wish to remove yourself from our mailing list however, go to Monitor Newsletter

You can download Monitor as a pdf file from https://www.windmill.co.uk/monitor/monitor195.pdf

Any questions, comments or data acquisition stories, get in touch via email, Twitter or Google+.

Contents

* Windmill helps research crop efficiency

* How to log four streams of data at different rates

* Excel Corner

* DAQ News Round-up

Windmill helps Research Crop Efficiency

One of the main environmental factors limiting productivity of wheat crops is nitrogen availability. Cereals need large amounts of nitrogen to increase maximum yield. This has meant that fertiliser application has increased from 1.3 million tonnes in 1930 to 90 million tonnes in 2004. It gets worse: researchers say that by 2050 fertiliser application will reach 240 million tonnes. This could be disastrous as excess nitrogen application can contaminate ground and surface water.

To reduce the application of nitrogen fertilisers, European policies encourage an increase of nitrogen use efficiency (or NUE) through crop management and plant breeding.

Spanish researchers - Aranjeulo, Cabera-Bosquet, Araus and Nogues - are investigating the processes conditioning nitrogen use efficiency in the hope of increasing crop productivity. They grew plants in two controlled environment chambers. The air of each module was sampled every 5 minutes, carbon dioxide concentration was analysed and air probes were placed in the centre of each module. They used Windmill Test Sequence software to record the data collected via a Microlink 751 data acquisition unit.

Test Sequence automates measurement and control tasks by running a text file of commands. The software understands a total of 47 commands, all specifically for data acquisition and control.

The results are published in the journal Plant Biology.

Further Reading

Windmill Test Sequence

https://www.windmillsoft.com/daqshop/test-control.html

Microlink 751: Multi-Function Data Acquisition and Control

https://www.windmillsoft.com/daqshop/daq-usb.html

Aranjuelo, I., Cabrera-Bosquet, L., Araus, J. L. and Nogués, S. (2013), Carbon and nitrogen partitioning during the post-anthesis period is conditioned by N fertilisation and sink strength in three cereals. Plant Biology, 15: 135–143. doi: 10.1111/j.1438-8677.2012.00593.x

http://onlinelibrary.wiley.com/doi/10.1111/j.1438-8677.2012.00593.x/abstract

Questions on Using Windmill: How to Log Four Streams of Data at Different Rates?

Question

I have a requirement to log data automatically from a dial test indicator gauge. I would require the ability to log 4 streams of data at varying intervals, is this something that you would able to assist with?

Answer

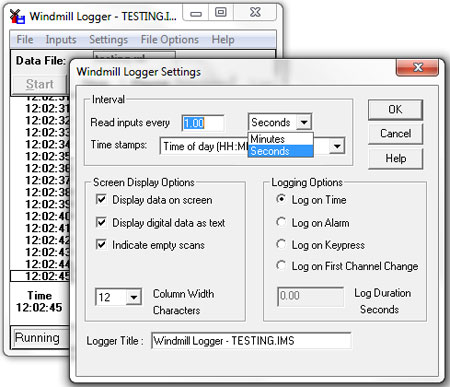

Yes, this is easy to do. Simply open four instances of our Windmill Logger program, connect one of the streams of data to each, and choose an appropriate logging interval.

To set the logging interval, select Logger's Settings menu. You can enter a logging interval down to as little as 0.2 seconds, which would give 5 readings a second.

Further Reading

For more on what you can do with Logger, see

https://www.windmill.co.uk/logger.html

To buy a copy of Logger for just £50, along with the other Windmill data acquisition programs, go to

https://www.windmillsoft.com/daqshop/rs232-modbus.html

Notes on how to connect a Sylvac Dial Gauge using Windmill are at

https://www.windmill.co.uk/sylvac.html

Excel Corner: Stepping Through Absolute and Relative References

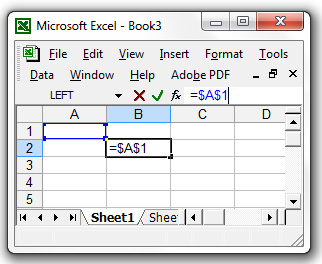

When referencing another cell in Excel, by default Excel will use a relative reference. It has a shortcut though, to quickly change this to an absolute reference. Position your cursor in the function box and press the F4 key. This will step through the different combinations of absolute and relative references: A1, $A$1, A$1, $A1.

An Absolute Reference in Excel: Cell B2 is referencing cell A1

What are the differences between absolute and relative references?

Relative references change when a formula or cell reference is copied to another cell. Absolute references, on the other hand, remain constant, no matter where they are copied.

A relative reference depends on the position of the cell being referenced and the cell doing the referencing. For example, If cell B2 referenced cell A1, Excel actually sees the A1 reference as being "one up and one left from B2". If you copy the contents of B2 to cell D4, D4 will reference C7, which is one up and one left from D4. If, instead, you want D4 to reference cell A1, you need an absolute reference. To make a reference absolute you add a dollar sign before it.

You can have a combination of absolute and relative references. So the column number might be an absolute reference and the row letter a relative reference, or vice versa.

Read more Excel tips at https://www.windmill.co.uk/excel/excel-tips.html.

DAQ News Round-up

Welcome to our round-up of the data acquisition and control news. If you would like to receive more timely DAQ news updates then follow us on Twitter - @DataAcquisition or Google+ - https://plus.google.com/107072683025496630222/

Automated imaging system looks underground to help improve crops

Researchers have developed an automated imaging technique for measuring and analysing the root systems of mature plants.

Source: Georgia Tech

http://www.news.gatech.edu/

Sensors could make car accidents obsolete

Volvo has developed a new safety feature that it believes has the potential to eliminate deaths and injuries by its cars and trucks by 2020. The system uses a suite of discrete sensors to provide comprehensive 360° coverage of the immediate area around the car every 25 ms

Source: New Electronics

http://www.newelectronics.co.uk/

Navy tests swarming unmanned boats

The US Navy have announced a breakthrough for swarming technology during a demonstration with small unmanned boats. By installing sensors and software on existing Navy manned patrol craft, they converted them to unmanned surface vehicles.

Source: Association for Unmanned Vehicle Systems International

http://www.auvsi.org/6102014onr

Robots set sail on scientific mission

A fleet of seven aquatic robots has set sail to collect scientific data about ocean processes and marine life. They are carrying a range of instruments. As well as measuring the temperature of the water and the weather conditions at the ocean surface, they can detect the density of plankton in the water and listen for clicks and whistles of dolphins and porpoises. The project has been described as the most ambitious of its kind in Europe.

Source: The Engineer

https://www.theengineer.co.uk/

* Copyright Windmill Software Ltd

* Reprinting permitted with this notice included

* For more articles see https://www.windmill.co.uk/

We are happy for you to copy and distribute this

newsletter, and use extracts from it on your own web

site or other publication, providing the above notice

is included and a link back to our website is in place.

For previous issues by subject see https://www.windmill.co.uk/monitorindex.html

FREE DATA ACQUISITION SOFTWARE

As a thank you for subscribing we offer you the

ComDebug data logging and Com port trouble-shooting

software for free. Log data over RS232, RS422, RS485

or Modbus. Also included is a free month's trial of the

Windmill 7 logging, charting and control programs.

SUBSCRIBING OR CANCELLING SUBSCRIPTION Visit https://www.windmill.co.uk/newsletter.html and add or remove your e-mail address.

Windmill Software Ltd, PO Box 58, North District Office,

Manchester, M8 8QR, UK

Telephone: +44 (0)161 834 6688

Facsimile: +44 (0)161 833 2190

E-mail: monitor@windmillsoft.com

https://www.windmill.co.uk/

https://www.windmillsoft.com/

Google+

Subscribe to Monitor

Comments

Tip: For a speedy response, when using Google+ comments alert us by adding +Windmill Software