Monitor - ISSN 1472-0221

The Newsletter for PC-Based Data Acquisition and Control

Issue 250, July 2019

Welcome to the 250th issue of Monitor! Thank you very much for subscribing. We've been going nearly 21 years - quite a long time for an internet-only publication. We sent our first issue when Google was in its infancy and Wikipedia hadn't been born.

One of our earliest newsletters covered choosing how to connect data acquisition devices to a PC - including over GPIB and ISA-bus - now rarely used. Other early topics continue to be relevant though, such as comparing temperature measurement techniques (issue 5). For a full archive of back issues see windmill.co.uk/newsletter.html

The newsletter really took off when we started offering data acquisition software to our readers. We still do but without the technical support. To get your copy of the Windmill measurement and control software for RS232, RS485, Modbus and Ethernet devices contact monitor@windmillsoft.com.

As always we welcome you comments and questions to monitor@windmillsoft.com. You can download this issue as a pdf file from https://www.windmill.co.uk/monitor/monitor250.pdf.

Contents

* Solving Manure Problems

* Your DAQ Questions Answered: High Speed Logging

* Data Acquisition News Round-Up

Solving Manure Problems

Web link: https://www.windmill.co.uk/logging-moisture-pellets.html

Cattle manure has always been a valuable source of nutrients for crops. It contains nitrogen, phosphorus and potassium and improves the chemical and physical properties of the soil. Its drawback though is that its bulk means it can be costly to transport. Also, heaps of manure have a risk of contaminating the environment with run-off to rivers. Pelleting is one of the ways to solve these problems and researchers have been investigating the physical properties of the pellets for efficient storage and transport, and how they are affected by moisture.

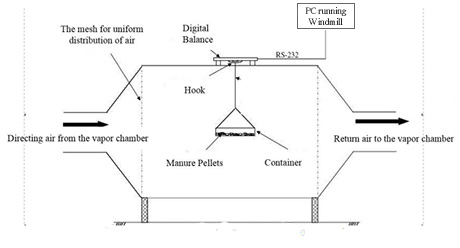

The amount of moisture in the pellets changes their durability and density. Scientists Mansoureh Pourjafar1 and Javad Rezaeifar conducted moisture absorption tests in an air-tight chamber (1.8 m x 0.9 m x 0.9 m). They supplied conditioned air using a temperature-humidity conditioner with temperature-relative humidity combinations of 45 oC at 70% and 80% humidity.

To conduct a test, the researchers placed 100 g of pellets in the sample container and hung it onto the weigh-below hook of a digital balance (accuracy of 0.01 g). They exposed the sample to the conditioned air for a maximum of 48 hours. After this time the pellets would either not absorb any more moisture or would have almost disintegrated. They used Windmill software to continually record the weight of the sample every 30 minute throughout the duration of the experiment. The software ran on a PC and connected to the balance over an RS232 interface.

The Windmill software that the researchers used is available for free to Monitor subscribers. Email monitor@windmillsoft.com for your copy

Further Reading

Some Physical Characteristics of Pellets from Cattle Manure, Mansoureh Pourjafar and Javad Rezaeifar, Bioscience Research 2019 16(2):898-908.

Your Data Acquisition Questions Answered: High Speed Logging

Question

Hello I have a question regarding Windmill 751 - what is the maximum sampling rate the equipment can support? We notice that the maximum rate for the analog channels is 0.02 second. We require a sampling rate of 500 Hz. Is that possible using Windmill 751?

Answer

If, instead of the Microlink 751, you use the Microlink 770, you can sample data at up to 100000 Hz. You can measure voltage, temperature, strain, pressure and current with the 770 and an appropriate conditioning unit. The Microlink 751 has more noise-reduction facilities and so samples at a lower speed - up to 50 samples-per-second for one channel of data and 200 samples-per-second in total.

More details are at Microlink 770: High Speed Data Acquisition or email sales@biodataltd.com.

DAQ News Round-up

Welcome to our round-up of the data acquisition and control news. If you would like to receive more timely DAQ news updates then follow us on Twitter - @DataAcquisition - or grab our rss feed.

Sensor could shake up earthquake response efforts

The technology - which autonomously captures and transmits data depicting the relative displacement between two adjacent stories of a shaking building - is able to provide reliable information about building damage immediately following an earthquake, and could expedite efforts to safely assess, repair, and reoccupy buildings post-quake.

Source: Berkeley Lab

https://newscenter.lbl.gov/

Vegebot uses machine learning to harvest lettuce

Although it is the most common type of lettuce grown in the UK, iceberg is easily damaged and grows relatively flat to the ground, presenting a challenge for robotic harvesters.

Source: University of Cambridge

https://www.cam.ac.uk/

Improving sensor accuracy to prevent electrical grid overload

New current sensors introduce errors when assessing current through iron conductors, according to evidence from researchers at the Czech Technical University.

Source: Eureka Alert

https://www.eurekalert.org/

A new sensor for light, heat and touch

Swedish scientists have developed a sensor that combines pyroelectric and thermoelectric effects with a nano-optical phenomenon.

Source: Linkoping University

https://liu.se/

* Copyright Windmill Software Ltd

* Reprinting permitted with this notice included

* For more articles see https://www.windmill.co.uk/

We are happy for you to copy and distribute this

newsletter, and use extracts from it on your own web

site or other publication, providing the above notice

is included and a link back to our website is in place.

For previous issues by subject see https://www.windmill.co.uk/monitorindex.html

SUBSCRIBING OR CANCELLING SUBSCRIPTION Visit https://www.windmill.co.uk/newsletter.html and add or remove your e-mail address.

Windmill Software Ltd, PO Box 58, North District Office,

Manchester, M8 8QR, UK

Telephone: +44 (0)161 834 6688

Facsimile: +44 (0)161 833 2190

E-mail: monitor@windmillsoft.com

https://www.windmill.co.uk/

https://www.windmillsoft.com/