Monitor - ISSN 1472-0221

The Newsletter for Data Acquisition and Control

Issue 284 September 2022

Welcome to Monitor, thank you for subscribing. The month, methods of timing and counting for many applications.

You can download Monitor as a pdf file from https://www.windmill.co.uk/monitor/monitor284.pdf.

Contents

* Timing and counting to measure speed, quantity, power consumption, machine on-time...

* Your Data Acquisition Questions Answered: Multichannel logger for R&D

Timing and counting to measure speed, quantity, power consumption, machine on-time...

Web link: https://www.windmill.co.uk/timer-counter-daq.html

Timing and counting have many applications in data acquisition. But which method to choose, and what to consider when setting up your measurement system.

No missed counts

For simple counting applications the main concern is that counts shouldn't be missed. When software reads the counter regularly for long periods, it is sensible to reset the counter to zero each time. You should also consider whether the count will exceed the capacity of the counter. A 16-bit counter will count up to 65535. Cascadable counters allow a carry count to be used to join two counters together: two 16-bit counters become one 32-bit counter. When a counter reaches its maximum count it produces a voltage pulse. This is then used as an input to another counter, thus continuing the count.

It is often useful to have an output latch facility. This is storage in hardware for the count. On a command from software, the contents of all counters are simultaneously transferred to their output latches. This means that you can take a snapshot of the counters without disturbing the on-going count, especially important with cascaded counters.

Measuring speed or power consumption

Frequency measurement works by counting pulses over a defined gate time, typically between 0.1 and 10 seconds. The gate time should be long enough to count sufficient pulses to give a good resolution of the frequency. The longer the gate time, though, the less often the frequency can be updated. Some hardware, like the Microlink 840, will also record the maximum, minimum and average frequency. Frequency measurement is useful when measuring speed or the rate of power consumption.

The Microlink 840 for data logging and counting

Period timer

A period timer measures the time taken for a number of cycles of the input signal to occur. At the end of each measurement the counter resets to zero. You can use this, for instance, to measure the speed of a conveyor belt by timing the interval between consecutive pulses.

Time on and off - measuring machine uptime

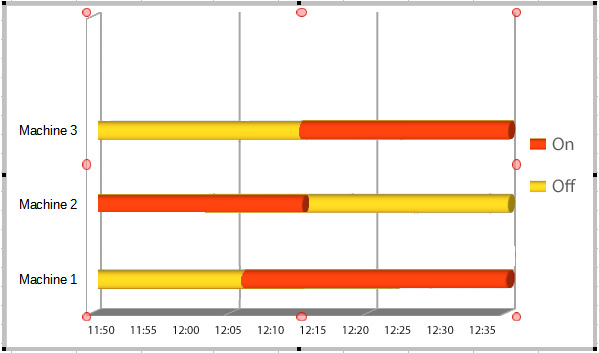

Some hardware will also measure the time that a signal is true, or the time between a start and stop pulse. You could use this to record the time when a machine is running. The timer will record how long the On signal is true and software calculates the percentage of time the machine is in use simply by comparing the total count with elapsed time.

More Information

For more on your counting or timing application, please contact Windmill Software - sales@biodataltd.com.

Your Data Acquisition Questions Answered: Multichannel logger for R&D

Question

"For our current R&D project we need measure strain gauge in full, half and quarter bridge (Wheatstone bridge). We need multichannel (minimum 4 channels) data logger, with minimum sampling frequency 4 kHz for each channel and excitation voltage for bridges. Data logger must have function for storing measured data with timestamp and export data to .csv or other format for further data processing in PC. Can you offer data logger which meets these requirements? Also, can you offer also power supply for strain bridges? Have you experience what power supply with voltage 0 - 24 V is the best?.

Answer

For fast applications use the Microlink 770 together with a Microlink 594 strain guage connection box. For slower applications (up to 80 readings per second) then the Microlink 751-SG which communicates over USB, or the Microlink 851-SG which communicates over Ethernet or Internet, would be good choices. Each of these accept 16 analogue input channels.

We have found that an ordinary plug-top power supply is good for this sort of application. They are quite stable now. Probably 5V or 9V would be best. The higher the voltage, the more the supply heats the strain guages, which can affect the readings.

For more information see https://www.windmillsoft.com/daqshop/strain-data-logger.html, https://www.windmillsoft.com/daqshop/high-speed.html and https://www.windmillsoft.com/daqshop/strain-measurement.html