Monitor - ISSN 1472-0221

The Newsletter for Data Acquisition and Control

Issue 295 October 2023

Welcome to Monitor, thank you for subscribing.For your free copy of Windmill data acquisition software email monitor@windmillsoft.com.

You can download Monitor as a pdf file from https://www.windmill.co.uk/monitor/monitor295.pdf.

Contents

* How often to Calibrate Measurement Instruments?

* Your DAQ Questions Answered: Data logging to Access database?

How often to Calibrate Measurement Instruments

Web Link: https://www.windmill.co.uk/drift-recalibration.html

Measurement and control devices are tested and calibrated to international standards before delivery. Over time, though, they will lose their accuracy and measurements will "drift".

Drift is a slow variation of a performance characteristic such as gain or offset.An offset drift results in a reading other than zero, for a zero condition. A gain drift is an error multiplied by the measured value. A gain drift of +/-0.05%, for example, means that the measurement will be out by 0.05%.

Drift is due to ageing components or environmental changes such as changes in temperature or humidity. It is especially significant when you are measuring low-level signals (a few microvolts) over long periods of time, or in difficult environmental conditions.

The way to deal with drift is to re-calibrate the instrument periodically. Calibration compares the instrument's actual performance to an accuracy standard. To do this you may need to return the instrument to the manufacturer or receive an on-site visit from them. You will then receive a calibration certificate which will be valid until the next recommended calibration date, often a year later. The higher the accuracy required, the more frequently the instrument will need to be calibrated.

Some instruments, like many in our Microlink range, are able to re-calibrate themselves periodically. They measure a reference voltage and compensate for offset and gain drifts.

Self-calibration is useful for long term monitoring as it means that drifts will not accumulate. You need to be careful not to set the re-calibrations too far apart as this can lead to small discontinuities in the recorded data as the re-calibrations occur.

Further Reading

Measurement devices which auto-recalibration

Your DAQ Questions Answered: Data logging to Access database?

Question

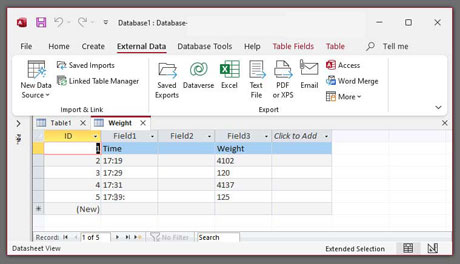

"I was wondering if you could help me, I am going to customise our existing access processing software. We are going to integrate a weigh scale, the existing weigh scale has a RS232 interface and accepts input to tare and zero the scale by using a ASCII string and also outputs the weigh data. I was looking at your data logger, would this be able to send and input back to the weighead to zero/tare the scale before a box of powder is placed on the scale. I was looking at that if Microsoft access can send a signal to the Windmill data logger then this sends the signal to the weigh unit, once this has happened the box of powder will be initially weighed, then taken off the scale. Once used, the box of powder will be placed back on scale and the Access database will save both the full and empty box weights. Is this practical with your data logger software please? "

Answer

Microsoft Access could send a message through DDE to the Windmill system which would send an RS232 message to the weighscale to tare the reading. Similar stages could then get back the readings of the weights before and after use. If your computer does not have RS232 ports, you will need a RS232-USB converter. Make sure you have the same settings - baud rate etc - for Windmill, the weigh scale and the USB converter.